11 Good Reasons To Select HARRIS Troidal Transformers

1. Quality

The HARRIS logo on your toroidal tarnsformer is your guarantee of quality and safety . All facilities produce to the highest standards and have many internationally recognized approvals including VDE 0550 and IEC 601.

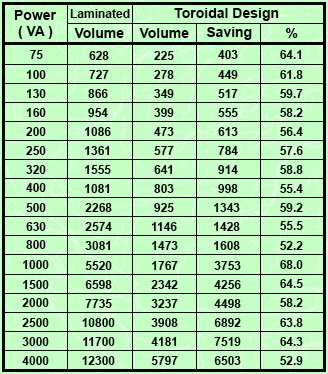

2. Volume Reduction

Space savings of up to 60 % when supplied with mounting brackets and terminal blocks for drop-in laminate replacement and up to 64 % when supplied with flying leads instead of terminal blocks . ( Many times it is easier to run the lead from the transformer to the equipment rather than the reverse) .

For sizes up to 1000 VA, savings can be even greater as a centering washer and single center screw or bolt will usually suffice , eliminating the need for a mounting bracket.

for toroidal VS. laminated design

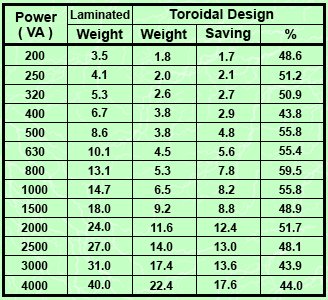

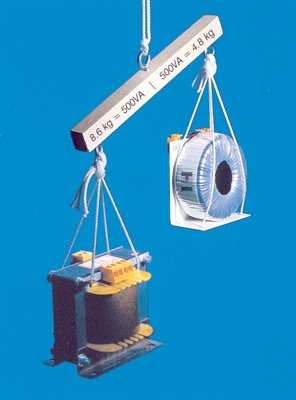

3. Weight Reduction

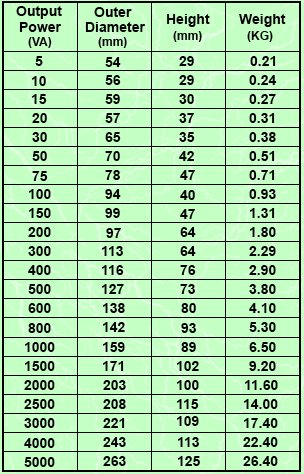

Up to 55% savings (more when used with a centering washer and screw or bolt) . Typical weights are shown as below .

for toroidal VS. laminated design

4. Higher Efficiency

The toroidal core has the ideal shape for producing a transformer with the minimum amount of material . All windings are symmetrically spread over the entire circumference of the core making the wire length very short . this results in lower winding resistance and higher efficiency. Ahigher flux density is possible as the magnetic flux is in the same direction as the rolling direction of the silicon steel core. A higher current density can flow through the wire as the entire surface of the toroidal core allows efficient cooling of the copper windings . The iron losses are very small – typically, 1.1 watt/kg at 1.7 Tesla and 50/60 Hz – giving very small magnetizing current which contributes to the excellent temperature rating of the toroidal transformer. HARRIS toroidal transformers are manufactured with the highest quality materials which allow a savings of approximately 50% against conventional laminated transformers as well as significant space savings against other toroidal manufacturers which utilize lower grade steel in their production .

5. Flixible Dimensions

HARRIS toroidal transformers offer a high degree of dimensional flexibility compared with conventional laminated transformers . Since cores are produced in our own core manufacturing and annealing facilities it is possible to make a core to virtually any diameter and height. Our engineers work closely with the customer’s design group and can usually tailor a toroidal transformer to fit into tight spaces which would normally be inaccessible to conventional transformers.

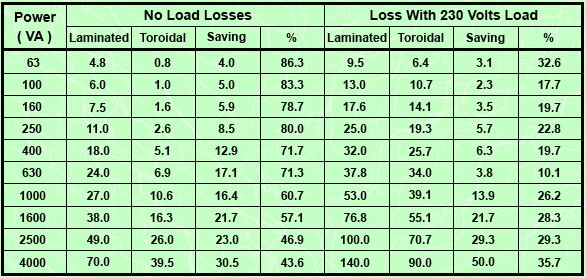

6. Energy Savings

Up to 86% at no load and 36% under load conditions. Realizing that the initial cost of the transformer is important , it is not by any means the entire story . international focus on the effect that entergy production has on the environment has resulted in a continuing increase in the cost of energy. The use of HARRIS toroidal transformers in place of conventional laminates offers significant energy savings as reflected by the chart below. Usually the energy cost savings realizable from the use of a toroidal transformer will pay for the transformer withi 2 to 3 years .

7. Easy Of Mounting

Standard mounting for sizes up to 1kVA is with a single metal centering washer and mounting screw or bolt making installation quick and simple.

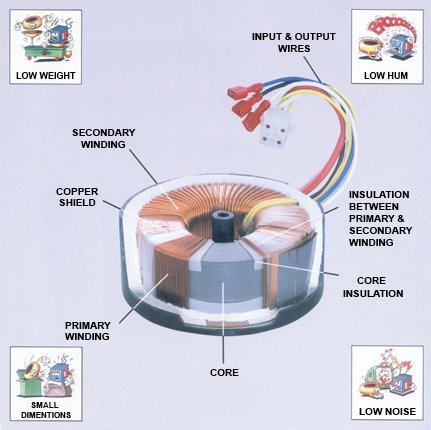

8. Noise Reduction

Because HARRIS cores are manufactured from a continuous strip of high grade steel with both ends welded . there are no air gaps and loose sheets of steel or laminations to cause vibration. This stability is further en-hanced by the copper windings which tightly surround the entire circumference of the core. The quality of the steel makes for low magnetostriction and minimum leakage losses. This combination of properties almost completely eliminates the hum and noise associated with conventional transformers and toroids manufactured using lower grades of steel.

9. Low Strayfield

Approximately 85-95 % lower than conventional laminated transformers. Achieving low levels of strayfield is an important consideration for the equipment designer as the phenomenon can create unwanted noise through interference with sensitive electronics. A toroidal transformer will generally offer a reduction of 8:1 in magnetic interference levels compared with traditional frame style laminate types. Over the years, the HARRIS Group design team has developed a range of successful techniques which can almost completely eliminate strayfield. These specialists will be pleased to work with you on your specific requirements.

10. Voltage Regulation Reduction

In HARRIS toroidal transformers, because of reduction of wire length ( wire resistance reduction ) and effective winding length increase ( series reactance reduction ) , the secondary voltage drop considerably decrease when compared to conventional transformers.

11. Price And Value

Highly developed production techniques coupled with material savings resulting from the more efficient design mean that today’s toroidal transformer is extremely costeffective when compared with similarly rated conventional units. When taking into account the other hidden benefits such as low strayfield, energy savings, smaller footprint and lower weight, the advantages become very significant. Generally , with toroidal transformers the larger the size the lower the cost when compared to traditional types.

TOROIDAL TRANSFORMER SPECIFICATIONS

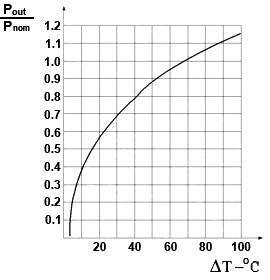

Temperature Rise

As diagram shows, standard toroidal transformers are designed for a temperature rise of 40 ^C to 60 ^C at nominal load. If a different temperature rise is required, HARRIS will also cater for this in the design phase.

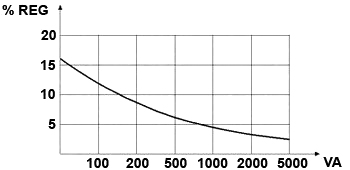

Regulation

Typical regulation performance for HARRIS transformers at full rated load are shown in below diagram , for power ratings from 15VA to 5KVA.

Frequency Range

Standard transformers are designed for operating frequencies between 48Hz and 60Hz, and operate up to a maximum of 450Hz. Transformer size decreases as frequency increases. Core materials used in frequencies up to 100KHz include thin tape wound nickel alloy, moulded powder, and sintered ferrite.

Duty Cycle

If the load is intermittent, then a smaller transformer can be used. As the output power in this case significantly exceeds the nominal power, secondary voltage will drop at a rate which increases in proportion to the current being drawn. However if intermittent use is specified, HARRIS engineers will cater for this requirement in the design phase.

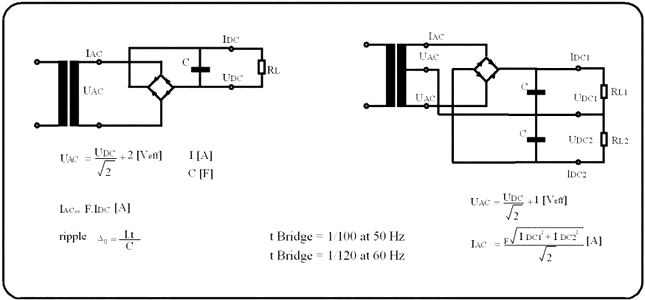

Rectification

When provided with information on a customer's circuit, i.e. type of rectification, value of smoothing capacitors, type of voltage regulators, etc., HARRIS will design a unit to provide the required DC outputs when operated in the specified configuration. However , as a guideline, below diagrams provide information for calculating approximate transformer AC values and size,which are primarily dependent on the size of smoothing capacitor to be used. The applied form factor "F” is rated between 1.1 and 2.5, depending on capacitor value.

In-Rush Current

The absence of air gaps in the core causes toroidal transformers to have a higher in-rush current when compared with conventional devices. For this reason, use of a slow-blowing fuse is recommended, particularly for output ratings in excess of 500VA. When safety considerations prohibit the use of slow blow fuses, HARRIS can recommend alternative in-rush current limiting devices to suit the specific application.

HARRIS TOROIDAL TRANSFORMER RANGE

Universal Application

HARRIS toroidal transformers meet modern day requirements for compact design and low magnetic interference field. Featuring a nearly ideal physical construction. The design engineer can expect excellent performance. Small size and weight ( approximately 50% of conventional transformers ), extermely low noise and low magnetic interference field make the toroidal transformer ideal for compact power supplies. Modern production techniques make it possible to produce toroidal transformers at practically the same prices as conventional transformers.

HARRIS toroidal transformer range are :

Power : 1 to 5000 VA

Voltage : 1 to 2000 V

Typical diamensions and weights of toroidal transformers are shown ahead.

Halogen Lighting Transformer

Finding a power transformer small enough in size yet big enough in performance for low voltage equipment has been solved by the HARRIS Group. Because we manufacture our own cores from the highest grades of steel available and have vast experience in core winding techniques, we can offer an infinitely variable choise of sizes. Because a hologen lighting transformer is essentially a safety isolating device. HARRIS has a range of transformers from 50 watt to 500 watt power ratings, with specific output voltages for Low Voltage lighting .

Medical Application

Leakage current is that current which can be conducted through the patient's body if the protective ground to the wall power cord is broken. Toroidal transformers can contribute leakage current through two paths : from primary to secondary, and from primary to mounting surface. Drawing on years of experience, our engineers can design toroidal transformers and mounting techniques that will minimize the transformer's contribution to system leakage. However , the equipment designer must also account for other components within the system that will contribute leakage current such as power cords, switches, line filters,and fuse holders.

Auto Transformer

An auto transformer permits smaller dimensions and a more economical overall design for applications where there is no requirement for electrical isolation. This results in considerable savings in size, weight and cost compared to an isolating toroid of similar power rating.

Quality Guarantee

All products comply with VDE 0550 as a minimum standard and will meet IEC 601 and VDE 0750 ( Medical Equipment) if specified.